Milling Inserts

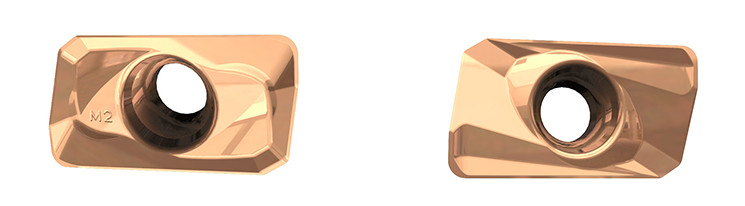

FM45 is suitable for P, K and M materials. The FM45 is used for face milling. FM45 features eight curved double sided cutting edges, sharp edges that generate low cutting force and cutting edge wipers that provide great surface quality. FM90 is suitable for P, K and M materials.

The FM90 is used for face, square shoulder and slot milling. These inserts have six cutting edges for extreme economical efficiency, cutting edge wipers that provide great surface quality and maintain outstanding perpendicularity during large cutting depths.

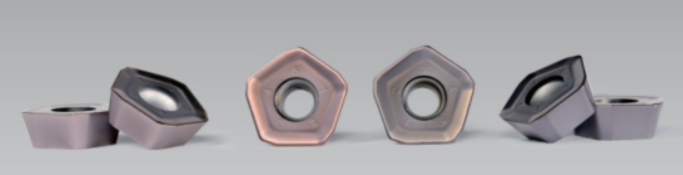

The HM series are high feed milling inserts that have a 1.5mm maximum feed and 2.0mm maximum cutting depth and five cutting edges. This in turn makes the HM series extremely efficient and economical. These inserts gain better surface quality due to the wipers. The inserts are suitable for face, ramp and plug milling.

APMT milling inserts are designed with unique spiral cutting edges for great perpendicularity, large rake angles that provides light and smooth cutting, double clearance angles for great cutting edge strength and outstanding surface quality due to the cutting edge wipers.

RPMT milling inserts have a positive rake angle designed to cut lightly and smoothly. Along with enhanced cutting edge strength treatment that provides great impact resistance on cutting edges.